Connections with Motor Drive

|

|

1) When MD is mounted, Power supply connector pushes up MD switch and thus cancels the power supply from the batteries installed in the camera. Thus MD is ready to supply Vcc1 to the circuit of the Nikon F3.

2) Depressing the trigger button of MD halfway closes Power SW of MD to turn on the transistor for power supply. Next, MD allows Vccl of camera to go high to approx. 3 V. Simultaneously, the signal of power-ON is provided with the circuit of camera, and Vcc2 goes also high as Power SW of camera is closed.

|

|

|

5) After the closing curtain's travel completes, Closing curtain SW closes to provide MD with the signal of film-advancing through Closing curtain SW and Film-advance completion SW. Then, with a del (ON-delay) of approx. 22 ms, MD starts to work for film-advancing.

|

|

|

Note: If depressing the shutter release button, opened Closing curtain SW will not allow MD to start film-advancing before the release button is freed. |

|||||||||||||||

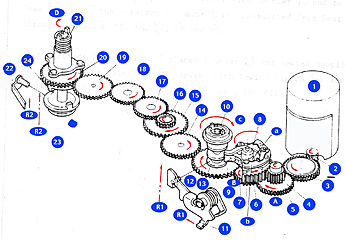

Mechanism - Driving Mechanism The MD-4 uses one motor to advance and rewind the film. But the clutch for advancing and rewinding allows the motor to rotate in the one direction. And, differing from the MD-2 and the MD-3, this motor drive unit releases the shutter by electric signal.

|

|

|

|

|

Standard LED voltage

| . |

Voltages in changing-over |

|

| Battery |

(A) from two-light up to one-light up |

(B) from one-light up to none |

| AA-type penlight |

10.2 +- 0.2V |

10.0 +- 0.2V |

| Ni-Cd MN-2 |

15.0 +- 0.7V |

14.8 +- 0.7V |

|

|

|

|

|

|

External Power Connector

Remote Control Connector

Use a screwdriver blade to short-circuit Pin 1 with Pin 2. Make sure that it releases the shutter.

|

| | | Back to Index of Nikon F3 Models Back to Pictorial History of Nikon SLRs |

|

|||||

|

|||||||

| About this photographic site | Contributions and Credits |

|

Home - Photography in Malaysia |